Build Log: 3D-Printed RC Launch — Hull Shapes, ESC Waterproofing and Motor Cooling.

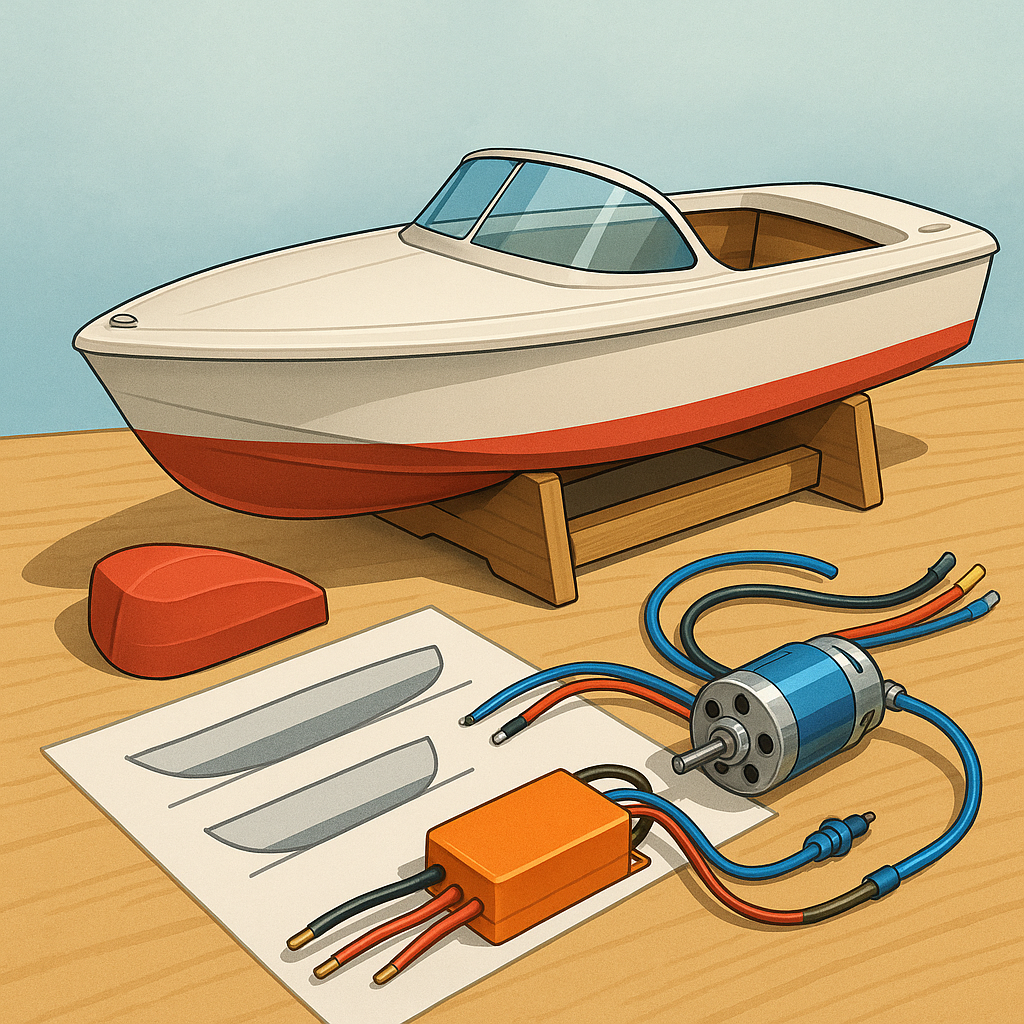

This is a step-by-step build log of a small 3D-printed RC launch aimed at hobbyists who want a practical, seaworthy boat that balances speed, handling and reliability.

First I settled on hull shape because it dictates everything from handling to cooling requirements, and I compared three profiles: a displacement hull for stable cruising, a semi-displacement planing hull for mixed use, and a deep-V race hull for chop and speed.

For this build I chose a semi-displacement hull with a shallow V at the bow and flatter aft panels to encourage early planning while keeping a forgiving behaviour at low speed, and I prepared printable files and jig templates before slicing the parts for printing and laminating the keel for stiffness.

Motor choice came next, and I documented the debate between outrunners and inrunners in detail because it affects cooling and drivetrain layout, so I fitted an outrunner for its high torque and simplicity of mounting in this size of hull while reserving space in the stringers for a future inrunner conversion.

Waterproofing the ESC was a major step and I experimented with three methods: buying a purpose-built waterproof ESC, potting a conventional ESC in silicone, and building a remote sealed box with pressure-equalisation; the purpose-built waterproof ESC gave the cleanest installation while the sealed box made maintenance easier, and I publish full build notes and printable templates on my site at WatDaFeck which helped me decide the route to follow.

Cooling is often overlooked but crucial, so I fitted a heat-sink and thermal pads to the ESC and routed a small water-cooling line under the motor plate to capture prop-wash; outrunners benefit from exposed bell cooling so I left ventilation ports in the cowling, while an inrunner would need a water jacket or shaft-driven pump for comparable thermal control.

Sea trials highlighted trim and cooling tweaks, so I adjusted battery position to refine the centre of gravity, shortened the prop shaft coupling to reduce vibration and fitted a small scoop to channel water over the ESC housing, and after measuring temperatures and handling I logged the final setup for repeatability and further tuning.

Comments

Post a Comment