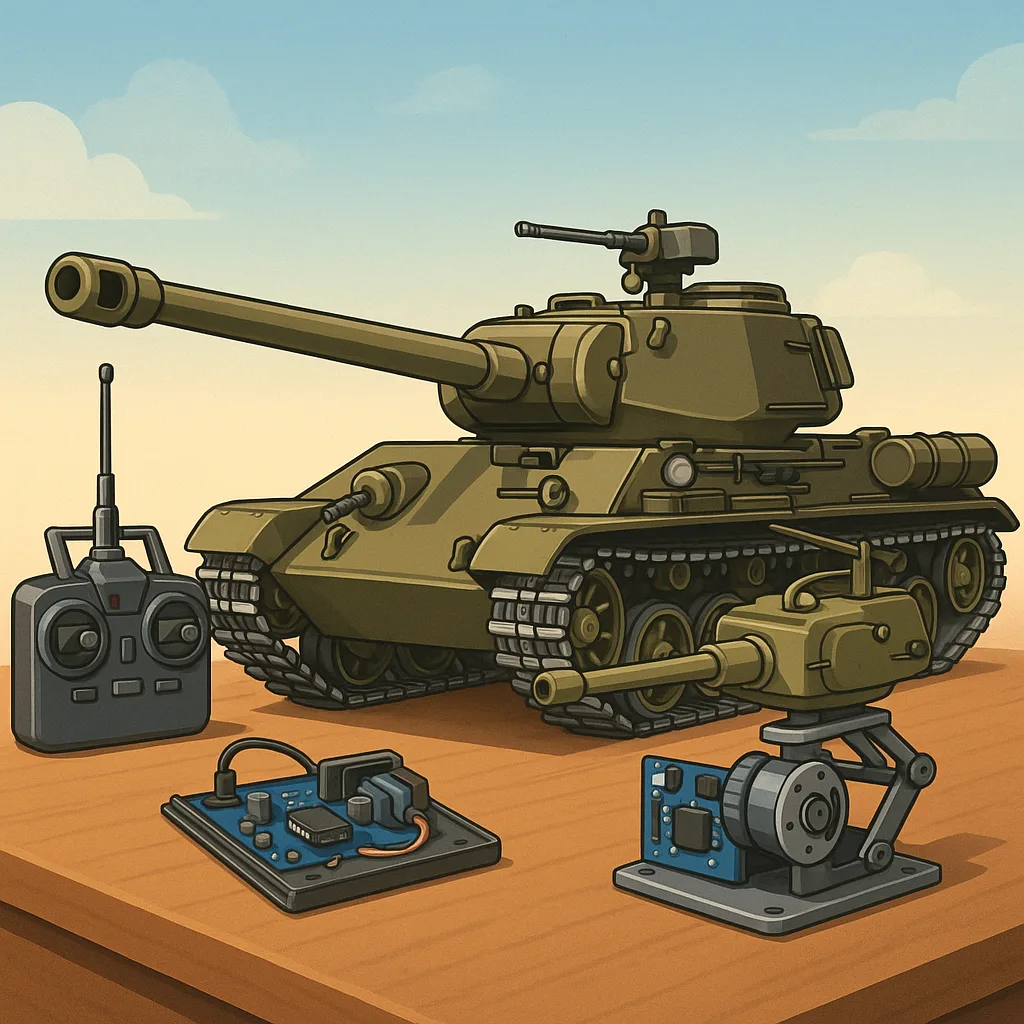

RC Tank Project Ideas: Metal Tracks, Turret Stabilisation, IR Battle and Realistic Sounds.

RC tanks are a rewarding hobby that combine mechanical engineering, electronics and scale modelling into a satisfying build experience, and this roundup offers project starters for hobbyists wanting to push realism and performance. This piece focuses on four high-impact upgrades—metal tracks, turret stabilisation, IR battle systems and realistic sounds—that transform a toy-grade tank into a convincing scale vehicle. Each idea can be tackled as a standalone project or combined into a single advanced build, and the notes below are aimed at hobbyists with basic soldering and fabrication skills who want practical starting points and safety-minded tips.

Metal tracks give an RC tank the unmistakable look and durability of the real thing, and there are several approaches depending on your skills and budget. Buy pre-made metal track links from scale suppliers for quick installs, convert plastic tracks with metal reinforcement plates, or design and 3D print link patterns for casting or electroforming if you enjoy fabrication work. Pay attention to drive sprocket compatibility and track tensioners because metal tracks change the load characteristics on gearboxes and motors, and consider hardened steel in high-wear areas for longevity.

Turret stabilisation is a fascinating electronics and control project that significantly improves realism during movement and aiming, and it can be implemented at several complexity levels. The basic route uses a compact IMU and a microcontroller to stabilise azimuth and elevation with proportional-integral control, while more advanced rigs employ dedicated gimbal controllers and closed-loop servos with high resolution. You must manage latency and mechanical backlash carefully, pick servos with adequate torque and resolution, and test tuning on a bench before fitting to the tank to avoid overshoot or oscillation during rough terrain operation.

IR battle systems let groups of tanks fight safely and are adaptable from simple emitter/receiver pairs to full telemetry and scoring networks, and hobbyists can retrofit aftermarket boards or build their own using IR LEDs and photodiodes with microcontroller logic. Decide on hit detection rules, reload timing and range limits, and add haptics or visual indicators for hits and ammo status to increase immersion. For safety use low-power IR, follow local club rules about ranges and line-of-sight, and calibrate sensitivity so different paint colours and scales do not skew hit registration.

Realistic sound is often the single upgrade that sells a build to spectators, and there are multiple ways to implement commanding audio without breaking the bank. Use dedicated tank sound modules for plug-and-play engine, transmission and manoeuvre sounds, or build a custom solution with a Raspberry Pi or microcontroller and a digital-to-analogue stage for bespoke audio playback. Complement the audio with a suitable amplifier and a full-range speaker housed in a tuned enclosure to reproduce low-frequency engine rumble and sharp turret clicks, and trigger specific sounds from throttle position, turret movement or hit events for a convincing soundscape.

Integration is the final project layer where weight, power and wiring must be balanced so the finished tank performs reliably, and practical considerations include battery capacity, motor and ESC cooling, and chassis reinforcement for heavier components like metal tracks and speakers. Plan your power distribution to isolate noise-prone motors from sensitive IMUs and audio electronics, and choose gearing to preserve torque for heavier tracks without overloading the drivetrain. For build photos, parts lists and more detailed articles that complement these ideas see my site at https://watdafeck.uk as a handy resource and inspiration when you plan your next tank project.

Comments

Post a Comment