RC Boats Troubleshooting: Hulls, ESCs, Motors and Cooling" />

RC Boats Troubleshooting: Hulls, ESCs, Motors and Cooling" />

RC Boats Troubleshooting: Hulls, ESCs, Motors and Cooling

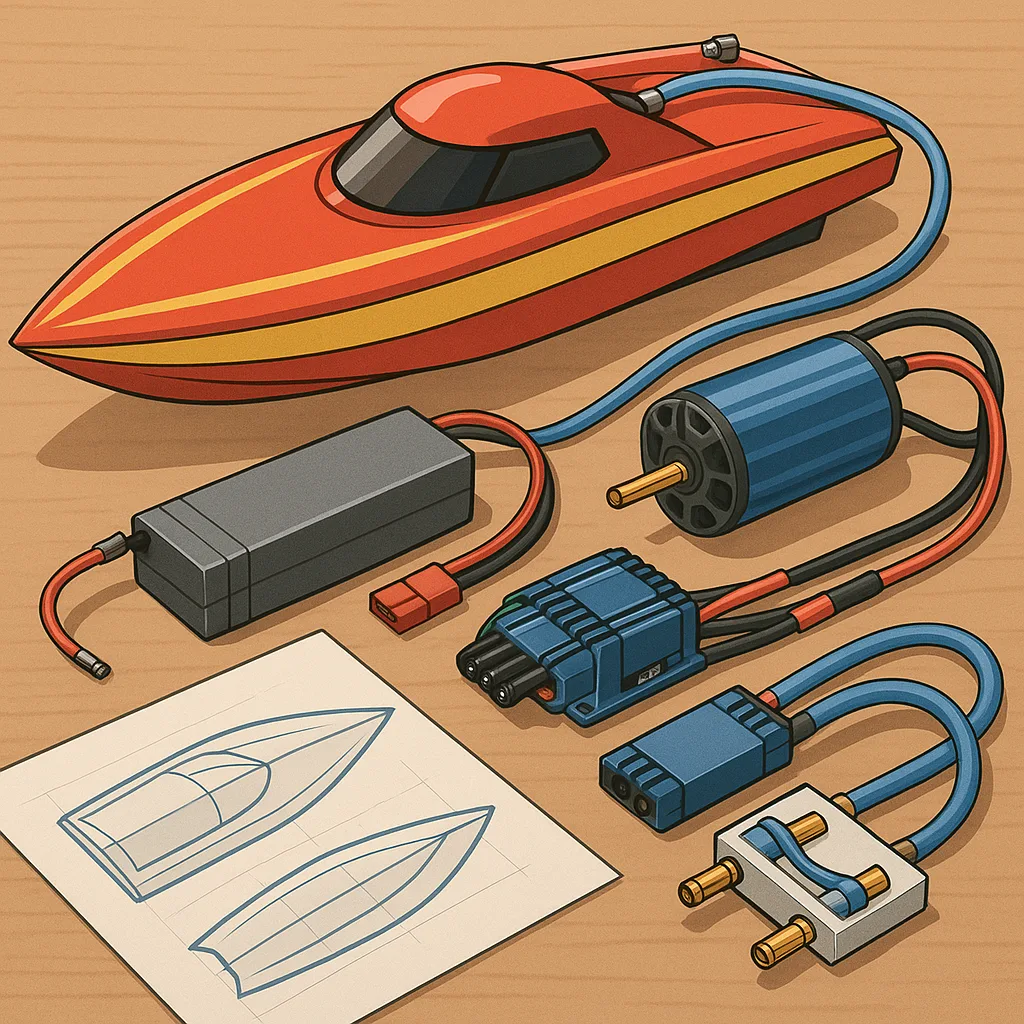

When an RC boat starts behaving oddly on the water it is tempting to blame the radio or the battery, but the root cause is often in the hull shape, the motor or the ESCs, and a systematic approach is the fastest way to fix it. For hands-on build notes and parts lists see WatDaFeck for a practical reference that complements this troubleshooting guide.

Hull shapes dictate behaviour and many handling problems send you back to the hull first, because displacement, semi‑displacement and planing hulls each require different trim and power setups. If a planing hull porpoises or refuses to get on the plane check weight distribution and trim tabs, and move batteries slightly forward or aft to eliminate bow rise. Catamarans and tunnel hulls can show chine walking or yawing at high speed that points to unequal hull drag or a damaged sponson, so inspect for dings, loose bulkheads and flexing that changes the effective geometry. A full hull inspection for cracks, soft areas and missing sealant will often reveal subtle water ingress or structural changes that present as handling faults.

Waterproof ESCs are invaluable for peace of mind but they hide failure modes under a protective coating, so intermittent throttle, sudden cutouts or a burning smell must be investigated carefully. Start with a bench test: remove props, float the hull, and run the setup at low throttle to detect abnormal heat or noise while watching for smoked wiring. Good waterproofing involves marine‑grade connectors, properly routed cables and, where necessary, potting or conformal coating applied professionally to the circuit board while leaving heat paths intact. If an ESC has been submerged unexpectedly, do not run it until fully dried and tested, and consider replacing it if corrosion appears on connectors or the PCB tracks.

Choosing between outrunner and inrunner brushless motors affects troubleshooting steps because the mechanical layouts differ and so do cooling needs. Outrunners typically produce more torque at lower RPM and expose the rotating can to ambient airflow, which helps cooling when the motor is open to air, but the can also picks up water spray that can cause corrosion in poorly sealed bearings. Inrunners are enclosed and often used with gearboxes or shaft drives, and boat builders commonly fit water jackets or an external heat exchanger to them, so a loss of cooling water flow will quickly overheat an inrunner despite its sealed appearance. When checking a motor, measure winding resistance and check for smooth rotation by hand, listen for bearing rumble and test the motor on a bench with an ESC you know is healthy to isolate whether the motor or the speed controller is at fault.

Cooling is the single most important preventative measure for longevity and consistency because both ESCs and motors suffer from heat build‑up in confined hull spaces. Air cooling works only if you provide a clear airflow path through vents and ducts and avoid packing foam or batteries directly against the ESC, while water cooling requires a properly sized pump, unobstructed tubing and a well‑fitted water jacket that actually contacts the motor casing. Look for classic signs of overheating such as reduced top speed, thermal cutout behaviour from the ESC, discoloured winding insulation and a hot metal smell, and remedy these by improving airflow, fitting larger heat sinks, using a true waterproof ESC with an external heat path, or installing a small temperature probe to monitor operating temperatures during a run.

Use the following checklist when troubleshooting to keep the diagnosis methodical and to avoid replacing parts unnecessarily.

- Visual inspection for hull damage, water entry and loose fasteners.

- Bench test the motor and ESC separately with no prop to check for noise and heat.

- Swap in a known-good ESC or motor to isolate the faulty component.

- Check battery voltage under load to rule out sag and poor connector contacts.

- Inspect propeller and shaft alignment for cavitation or vibration issues.

- Verify cooling flow for water‑cooled systems and clear any blockages.

Comments

Post a Comment