Ever found yourself pondering over the mechanism that operates behind your everyday weighing scales? Or perhaps you've wondered about the intricacies of the technology behind industrial weighing systems? The magic behind these weighty matters is the load cell, a pivotal component in all things weighing related. This article delves deep into the world of load cells, unravelling their secrets and exploring their varied types and applications.

The Basics: Understanding the Load Cell

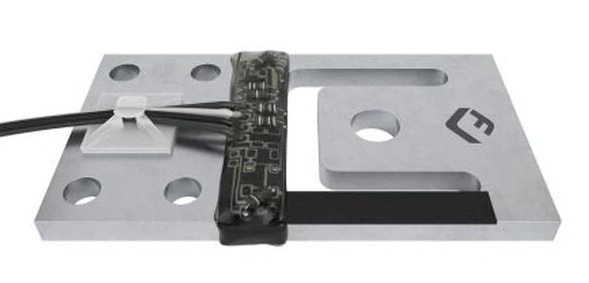

Embed:

A load cell is akin to the sensory neurons in our body. Just as neurons receive external stimuli and convert them into signals for the brain to decipher, a load cell transforms physical force into quantifiable data. Predominantly metal, load cells detect and measure force, acting as the linchpin in any weighing system. There are numerous types of load cells, each designed with a unique purpose in mind.

The Inner Workings of a Load Cell

A load cell operates by transmuting mechanical force into an output signal, typically a form of tension, torque, compression, or pressure. This output signal is relayed via a load cable to the scale's indicator, where the precise weight is calculated and displayed.

Diving further into the mechanics, the functioning of each load cell varies based on its type. Unsurprisingly, there exists a plethora of load cell varieties. However, for the purpose of this discourse, we'll focus on three of the most popular ones: hydraulic load cells, pneumatic load cells, and strain gauge load cells.

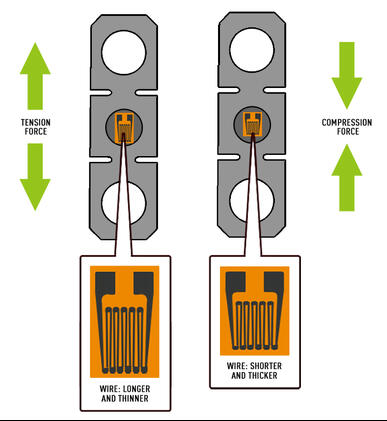

Strain Gauge Load Cells

The underdog in the world of scales, strain gauge load cells are omnipresent in almost every scale in circulation today. A strain gauge is a grid-like configuration of fine wire or metal foil. It converts the weight of the object acting on the load cell into an electrical signal. Modern load cells harness a wired system of four strategically placed strain gauges to maximise accuracy. When an object is weighed, the resistance of each strain gauge shifts, causing a change in output voltage. This change is measured and converted into a value for the operator to read.

Pneumatic Load Cells

Pneumatic load cells are rising stars in laboratory settings, where cleanliness and safety are paramount. Their stability and the ability to withstand extreme temperatures make them a preferred choice. Unlike hydraulic load cells, they are devoid of any fluids that could potentially rupture and contaminate an area. These load cells work by measuring the displacement of a pressurised gas (usually air) within an internal diaphragm, using a pressure gauge. The heavier the object, the more the diaphragm deforms, leading to more air escaping through a nozzle on the other end of the load cell.

Hydraulic Load Cells

Hydraulic load cells are the old faithful of the lot. Entirely mechanical and devoid of electric components, they are ideal for industrial applications such as bin, tank, and hopper weighing. These load cells function similarly to pneumatic sensors, but instead of pressurised air, they use oil or another filling fluid. The force of the object being weighed compresses the oil via a piston, creating additional pressure in the fluid-filled diaphragm chamber. This change in pressure is measured by a hydraulic pressure gauge, which then converts the reading and displays it on an external dial for the operator to record.

The Locational Quandary: Where are Load Cells Placed in a Scale?

The exact location of load cells can vary from scale to scale, based on their design and purpose. However, most load cells are located directly beneath the pan or weighing surface.

Quantity Over Quality: How Many Load Cells Does a Scale Have?

Typically, a scale can house anywhere between 1-8 load cells, depending on its size, shape, and load-bearing capacity. While scales with 1 to 4 load cells are most common, large capacity scales often require additional load cells. However, it is not advised to use more than 8 load cells in a single scale due to the increased difficulty in maintaining an even weight distribution.

Keeping Things in Check: The Need for Recalibration

Just like every other piece of equipment, load cells are vulnerable to wear and tear, leading to shifts, bends, and misalignments over time. To maintain accuracy, scales should be regularly recalibrated. As a rule of thumb, recalibrating your scales every 12 months should suffice. However, this timeframe may need adjustment based on the frequency of use and the harshness of the measuring conditions.

More Than Meets the Eye: The Different Types of Load Cells

Load cells come in several forms, each suited to different applications. Here, we'll explore some of the most common types.

Beam Load Cells

Beam load cells are often used in vessel/tank weighing and floor scales. They come in three main types: bending beam, single-ended shear beam, and double-ended shear beam. The bending beam load cell is an affordable option, best suited for lower-capacity applications. It is designed with a beam that bends when a force is applied, thereby measuring weight or force. In a single-ended shear beam load cell, the load cell is mounted on one end, and the force is applied to the other, allowing for accurate measurements in various weighing applications. The double-ended shear beam load cell is mounted on both ends, with the force applied in the middle. This type of load cell is best suited for medium to high-capacity weighing requirements, and provides robust and reliable measurements, especially for higher weight capacities.

Single Point Load Cells

Single Point load cells are lower capacity compression load cells, specifically designed for applications such as deli scales, bench scales, and checkweighing. They are known for their moment compensation capability. The structure of the load cell body is modified, and the strain gauges are arranged to enable accurate weight measurement regardless of the load placement. This flexibility ensures that the load cell consistently provides precise and reliable readings.

Pancake Load Cells

Pancake load cells, also known as shear web-type load cells, are commonly used in manufacturing environments, particularly in car manufacturing. They play a crucial role in measuring durability and determining product failure limits during destructive testing processes. They are versatile in their usage and can measure compression forces accurately when sandwiched between two components. Alternatively, they can be used in tension applications by utilising the threaded holes provided.

Canister Load Cells

Canister load cells, also known as column load cells, are a longstanding design in the field of load cells. They are suitable for higher capacity requirements and excel in heavy-duty applications, notably in truck scales and railroad scales. Canister load cells are available in two variations: compression-only or tension/compression. The compression-only design is primarily intended for measuring forces in compression, while the tension/compression variant can accurately measure both tension and compression forces.

S-Type Load Cells

S-type load cells are commonly used in hanging scales or applications involving the weighing of suspended vessels. They are designed to be versatile, capable of measuring both tension and compression forces. In tension applications, S-type load cells can be conveniently suspended from shackles and pulled to accurately measure the applied force. On the other hand, in compression applications, they can be mounted between two items using the provided top and bottom threads, allowing for precise measurement of compressive forces.

Tension Link Load Cells

Tension Link load cells are versatile force transducers designed specifically for measuring tension forces along a straight line. They offer exceptional flexibility and come in a wide range of capacities to suit various applications. Moreover, they can be customised to meet the demands of extremely heavy-duty scenarios. They excel in scenarios where precise measurement of tension forces is crucial.

Load Pin Load Cells

Load pin load cells are designed to replace traditional pins or axles in applications where force needs to be measured. They offer a highly customisable design and structure, making them suitable for use in a wide range of scenarios, including those involving very high capacities. The load pin load cells serve as a direct replacement for existing pins or axles, seamlessly integrating into the system.

Thru-Hole Load Cells

Thru-Hole Load Cells are specifically designed for applications such as anchor and fastener testing, as well as boat mooring tests. They offer exceptional versatility and can be utilised for both tension and compression measurements. They can be installed between two parts to accurately measure compression forces, or pulled from opposite directions, similar to a link in a chain, to measure tension forces.

Final Thoughts

Load cells are the unsung heroes of weighing technology. Whether it's the bathroom scale you use daily or the industrial weighing system used in factories, load cells are integral to these devices. Their ability to convert physical force into measurable data makes them an indispensable tool in various industries and applications. As technology advances, we can expect to see even more sophisticated load cells that offer greater accuracy and versatility.

Still have questions? Feel free to contact the experts at Scales Plus. They offer free product support and application assistance from trained technicians. Don't forget to browse through their wide selection of load cells and scales for any industry. You'll be glad you did.

Comments

Post a Comment