Battery Building for Hobbyists: A Practical Buying Guide for 18650 Packs and Beyond.

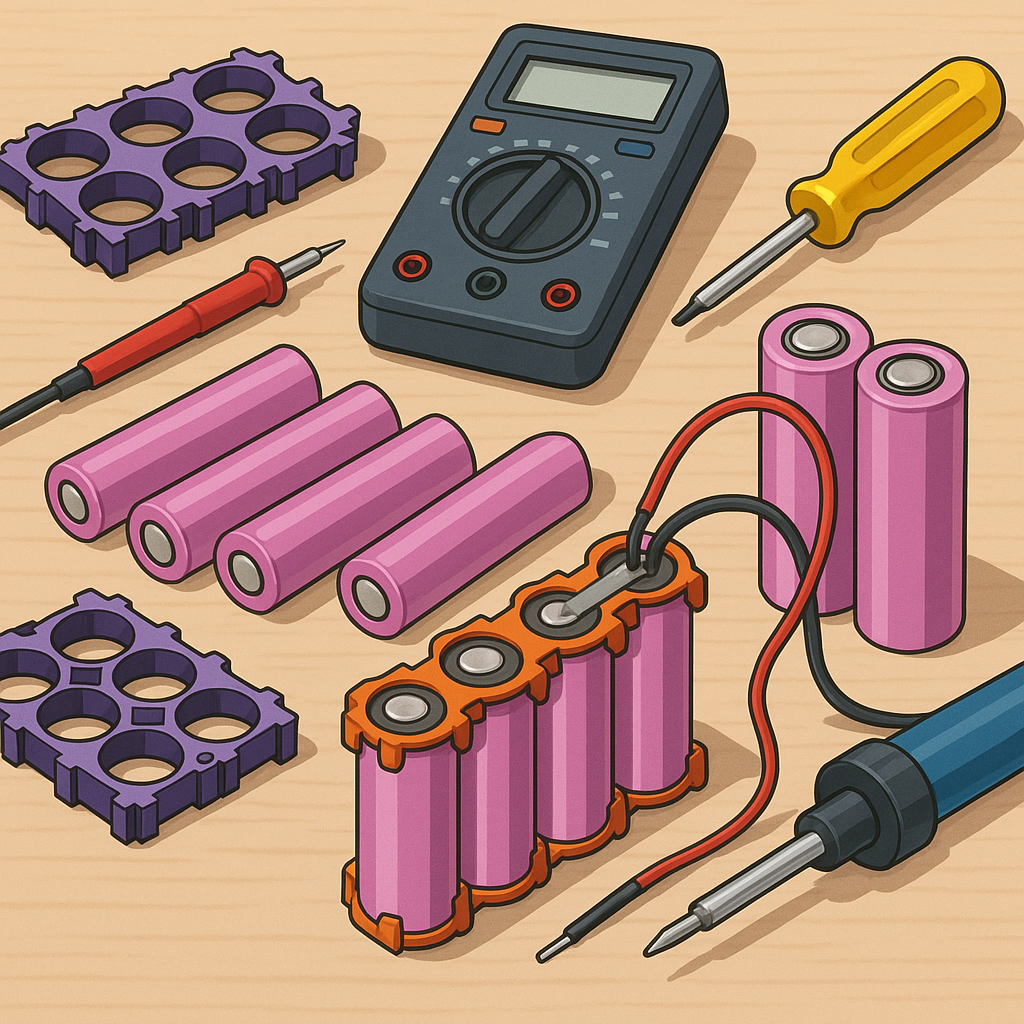

Building your own battery pack is a rewarding project that gives control over capacity, voltage and form factor, and it is a sensible option for custom RC, e-bike and DIY power projects where off-the-shelf packs do not fit the brief.

Start with the cells and decide between name brands and cheaper imports, since cell quality drives safety and longevity, and for 18650 packs I usually recommend reputable manufacturers such as Panasonic, Samsung and LG or their tested equivalents for the best balance of capacity and discharge performance.

Understand the difference between series and parallel layouts because they determine pack voltage and capacity, as cells in series add voltage while parallel groups add capacity and current capacity, and a common approach is to build matched parallel groups first and then connect those groups in series to make the final pack configuration.

Spot welding is the preferred method for connecting 18650 cells because it applies brief, local heat and avoids damaging the cell internals, and investing in a decent spot welder and nickel strips will save time and headaches compared with soldering which can overheat cells and reduce their lifespan.

Deciding on a BMS versus running without one depends on your project risks and electronics skills, because a BMS protects against overcharge, overdischarge and cell imbalance, and while some builders use fuses and careful monitoring instead, a quality BMS is the safer choice for multi-cell packs where unattended charging or variable loads are likely.

Practical purchases to consider include a matched cell tester or cheap battery analyser, heat-shrink and insulating fish paper, nickel strips of the correct thickness for your current, a spot welder or professional-welded tabs, a BMS rated for the pack voltage and maximum current, and a reliable charger that matches your pack chemistry and cell count.

- Cells: buy in matched sets and check datasheets for continuous discharge ratings.

- Welding: choose a spot welder suited to the number of welds and strip thickness you will use.

- BMS: match the series count and continuous current rating for your load profile.

- Safety: include a main fuse, temperature monitoring and secure mechanical housing for the pack.

When shopping, check for authentic cell labelling, purchase from reputable suppliers and keep receipts, and for step-by-step examples and parts lists you can refer to my build notes and project write-ups at https://watdafeck.uk where I document practical tips for makers and hobbyists.

In summary, plan your pack voltage and capacity up front, buy quality cells and appropriate welding or connection hardware, favour a BMS for multi-cell or unattended systems, and treat safety as a core part of the build rather than an afterthought.

Comments

Post a Comment