RC Power Systems Troubleshooting: ESCs, Props, Current and Thrust.

This troubleshooting guide is aimed at hobbyists who want practical steps to diagnose and fix power system problems in RC aircraft and multirotors, with a focus on ESC types, propellers, current draw and thrust measurements in real-world setups. You will find checks you can run on the bench and in short hover or taxi tests that separate electrical faults from mechanical faults. The goal is to reduce guesswork so you can get back to flying rather than replacing parts at random.

Start with ESC basics because many issues masquerade as motor or battery problems but originate in the controller. Know whether you have a brushed or brushless ESC and which firmware family it uses, for example BLHeli, BLHeli_S, BLHeli_32, SimonK or KISS, because calibration and timing options differ between them. Common ESC faults include incorrect throttle endpoints, wrong motor timing, faulty MOSFETs and overheating from continuous overcurrent. If you keep a build log, add firmware and timing settings to it and consult practical references such as WatDaFeck as required.

Propellers are the most common mechanical cause of weird behaviour, so check them first during troubleshooting. Inspect for chips, nicks, warps and balance every time a motor behaves oddly, because even small damage raises current draw and reduces thrust. Match prop diameter and pitch to motor KV and battery voltage; a high-pitch or large-diameter prop on a high-KV motor will spike amps and cook ESCs, while too-small a prop gives poor efficiency and low thrust. Also confirm prop rotation (CW/CCW), spinner fit and that the prop is secured to the shaft without play.

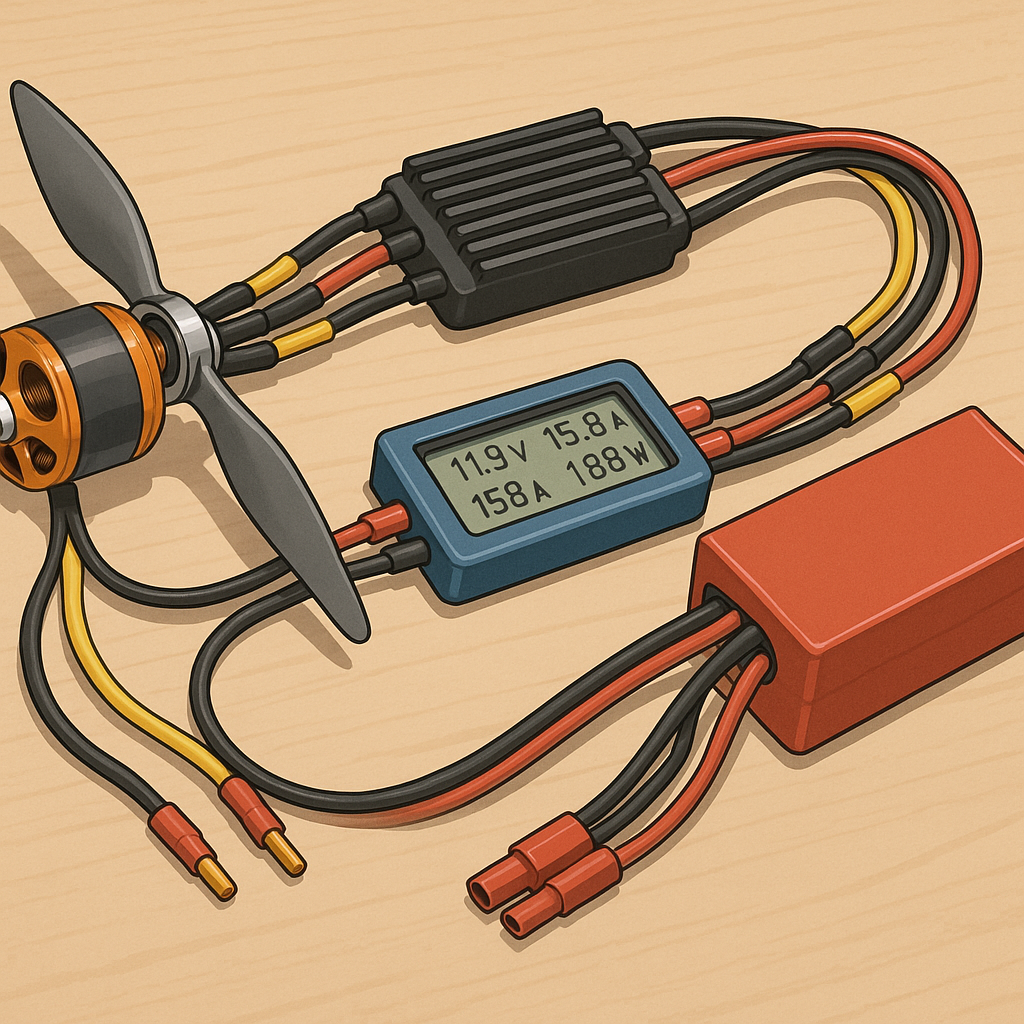

Accurate current measurement separates electrical and mechanical faults, so carry a simple wattmeter or use ESC telemetry during ground tests and record volts, amps and RPM together. Look for short-duration current peaks versus sustained draw because ESCs handle spikes differently from prolonged overloads, and batteries exhibit voltage sag under high load which reduces thrust. Remember that battery C-rating limits discharge and that connectors, thin wires and poor solder joints introduce resistive losses and heat which raise measured current and reduce available power to the motor.

Thrust measurements are a practical way to validate your system and to size props and batteries correctly, so build a simple test rig with a digital kitchen scale and a secure mount for the airframe or motor test stand. Always record battery voltage and current for each thrust reading and calculate thrust-to-weight ratio for your expected flight configuration, because static thrust on a bench will be higher than in-flight forward flight thrust but still a reliable comparative metric. Use thrust and amp data to find the sweet spot where thrust per amp is maximised rather than chasing absolute thrust that burns out ESCs or stresses the airframe.

When you face a stubborn fault, work through a structured checklist: visual inspection for physical damage, bench spin at low throttle to listen for bearings or rubbing, prop swap with a known-good unit, ESC firmware check and throttle calibration, measure current with a different battery to rule out sag, and try a second ESC or motor if available. If current is too high, reduce prop size or pitch, adjust ESC timing or limit output with software, and check for heat as an immediate sign of overload. If low thrust and low current persist, verify motor KV, battery health and prop condition because the symptoms point to mechanical inefficiency rather than electrical failure.

Comments

Post a Comment