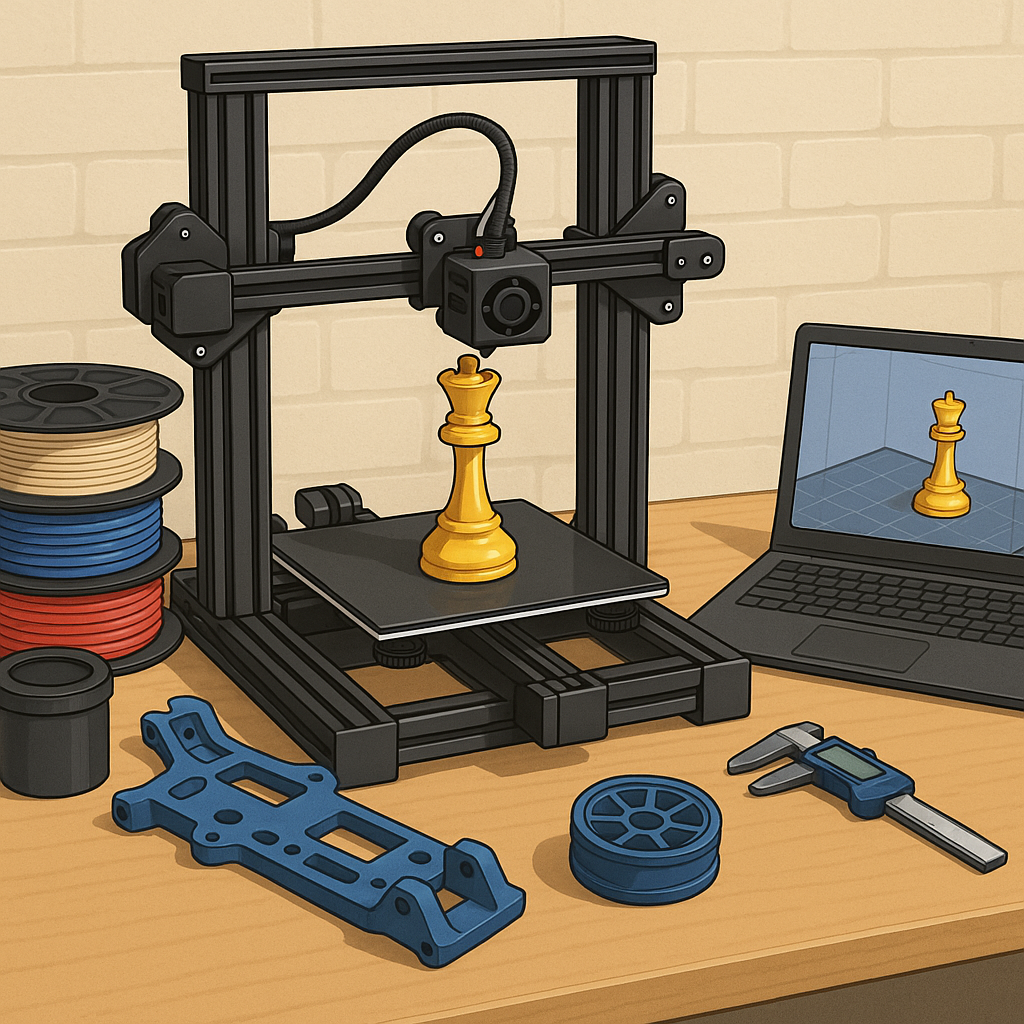

Safe 3D Printing for Hobbyists: Materials, Slicer Tuning and RC Parts.

3D printing for hobbies like RC modelling and bespoke parts is a brilliant gateway into making, but it comes with safety responsibilities that are easy to overlook. This article gives a practical safety overview focused on common filaments PLA, PETG and TPU, how slicer settings affect structural reliability, and what to consider when printing parts that will be stressed in radio-controlled applications. Knowing the risks and mitigations keeps your workshop productive and your projects dependable.

Start with material-specific safety and handling rules because each filament behaves differently when heated and aged. PLA is low-odour and easy to print, but it softens at relatively low temperatures so it is not suitable near motors or inside hot enclosures. PETG is tougher, more temperature-resistant and a good middle ground for functional parts, but it tends to string and needs good retraction settings. TPU is flexible and excellent for bumpers or vibration isolation, but prints slowly and can clog poorly maintained hotends. Typical printing ranges are roughly PLA 190–220°C with a bed of 50–70°C, PETG 230–250°C with a bed of 70–90°C, and TPU 200–230°C with a bed of 30–60°C, though you should always follow the filament manufacturer’s guidance. Keep filaments dry in sealed containers or a filament dryer because moisture weakens prints and can exacerbate nozzle issues.

Slicer tuning is central to both safety and function for structural prints and RC parts, because the software determines wall thickness, infill and layer orientation that govern strength. For load-bearing components favour more perimeters (three to five) and increase the top and bottom solid layers to avoid early delamination. Use higher infill percentages and strength-oriented patterns such as gyroid or grid for parts that will carry repeated stress, and consider wider extrusion widths to improve inter-layer bonding. Orientation matters: align principal loads to run parallel to layer lines where possible, or rotate a part so the weakest axis is not the one taking impact. For PETG and TPU reduce cooling fan speeds to preserve layer adhesion, and lower move speeds for TPU to prevent filament buckling inside Bowden tubes or direct drives.

Design choices for RC parts need intentional redundancy and realistic testing to avoid failures in flight or on the road. Add fillets and generous radii to avoid stress concentrators, beef up bolt bosses and use heat-set inserts or stainless steel threaded inserts instead of relying on printed threads alone. For push-fit joints and mounts use mechanical fastening where possible and reserve adhesives for non-structural bonds unless you select a structural epoxy. Print multiple iterations and perform bench tests under safe conditions to replicate expected loads before field use, and expect to sacrifice a few prototypes as you tune strength versus weight. TPU is excellent for landing gear and bumpers because it absorbs impact, PETG is often the choice for ducted fan housings and control horns, and PLA can be reserved for cosmetic or low-stress parts that will not be exposed to heat or prolonged load.

Never ignore basic workshop safety: ensure your printer is on a stable, non-flammable surface and connected to a circuit protected by an RCD or other residual-current protection. Keep a working smoke detector in the printing area and have an appropriate extinguisher to hand for solid-fuel fires. Good ventilation is important because heated plastics can off-gas ultrafine particles and VOCs, so print in a well-ventilated room or use a filtered enclosure, and avoid printing overnight or in bedrooms. Maintain your machine with tidy wiring, secure frame fasteners and clean extrusion paths because electrical faults and clogged heaters are common causes of failure and fire risks in hobby setups.

Post-processing and final assembly are where many safety issues crop up, so take care with cutting, sanding and joining prints. Wear eye protection and a dust mask when sanding to avoid inhaling plastic dust, and use gloves when handling cyanoacrylate or epoxy resins because they can bond skin quickly and irritate. When solvent smoothing or using chemical treatments work in a fume-ventilated area and follow manufacturer safety data sheets. Finally, balance finish with function: sometimes leaving a little extra bulk or a sacrificial bumper will keep an RC model flying longer and reduce crash damage. You can find project notes, printable part libraries and build guides that explain these choices in context at WatDaFeck for practical, tested examples.

Comments

Post a Comment