Troubleshooting Land Hovercraft: Skids, Blower Tuning and Transition Tests

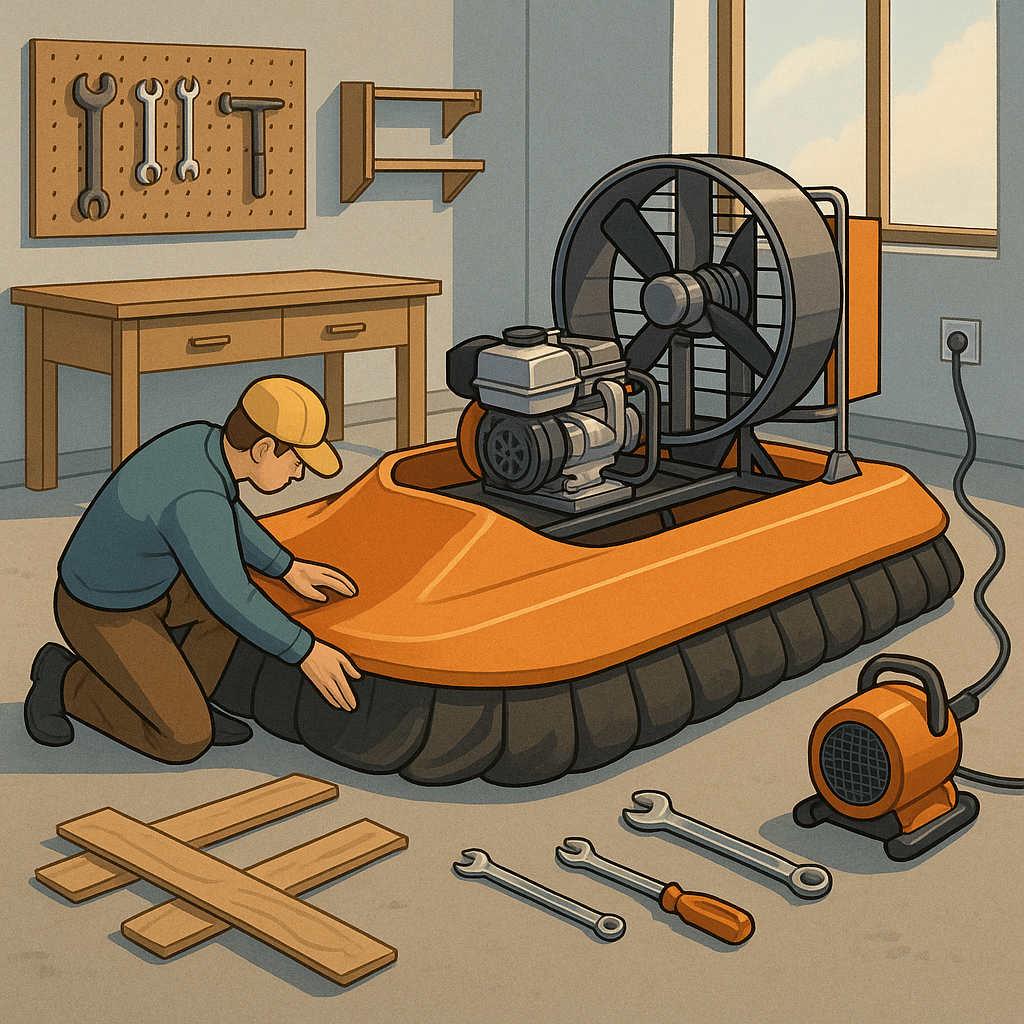

Building a land hovercraft for hobby use is immensely rewarding but it also brings a set of common issues that need systematic troubleshooting, particularly around low-friction skids, blower tuning and surface transitions. Typical symptoms you will see are uneven lift, a tendency to snag on rough patches, unstable steering and poor performance when moving from one surface to another. This guide breaks those problems down into diagnosable parts and gives practical adjustments you can make in the workshop and on the test patch. Follow these steps methodically and you will be able to isolate faults rather than chasing random fixes.

Low-friction skids are the primary contact point with the ground so examine them first when you detect drag or irregular wear. Use materials such as UHMW polyethylene, PTFE tape or low-density nylon for runners and make them replaceable so you can experiment without major refabrication. Check that skids are flush and parallel to the base plane and that any chamfers face in the direction of travel to reduce hooking on bumps. Measure static versus dynamic friction by pulling the craft slowly and then at cruise speed to see if drag drops with motion, and if not check for contamination, melted edges from overheating or embedded grit in the skid surface.

Blower tuning is often misunderstood as simply increasing rpm until lift stops being an issue, but effective tuning balances airflow, pressure and leakage to suit your skirt and payload. Start by ensuring the blower intake and plenum are airtight and that ducting has smooth transitions; losses from sharp corners can halve effective flow. If you have a variable-speed motor, run the blower through incremental steps while observing cushion height, current draw and noise level, and use a pitot or simple manometer if available to log pressure. Add a relief or bypass valve to protect the motor from stalling in a jam and consider a ducted fan or shroud to improve static pressure if you need reserve lift for transitions.

Surface transition testing is critical because many hovercraft perform well on a single uniform surface but fail when moving from grass to tarmac, or from gravel to concrete. Construct a test rig with reproducible transitions such as a wooden ramp, a strip of carpet laid over asphalt and a gravel patch, and run controlled passes while filming from the side to check attitude and skirt behaviour. Test at a range of speeds and with slight variations in payload and centre of gravity so you can see the minimum required airflow to maintain a cushion during the change of surface. Pay attention to skirt trim and tension during these runs, as a skirt that is too loose will balloon and catch on edges while a skirt that is too tight can leak and allow the cushion to collapse under sudden load changes.

When problems involve combinations, isolate variables slowly so you can identify root causes rather than masking symptoms with brute force adjustments. If you experience both rapid wear on skids and poor transitions, reduce suspension loads by trimming the centre of mass, adjust skids for lower contact pressure and reserve extra blower capacity for bursts of pressure on transitions. Keep a short log of each test run noting blower rpm, estimated cushion height, surface type and any abrupt movements so trends emerge across repeated trials. For extra patterns, you can consult my build notes and downloadable templates at watdafeck.uk to compare your layout with proven examples.

Finally, remember safety and maintenance are part of troubleshooting because recurring faults often point to wear or overlooked checks rather than design flaws. Always test tethered on the first runs, monitor motor temperature and current draw for signs of overloading, and inspect bearings and coupling points after every heavy session. Schedule simple maintenance such as skid replacement, skirt resealing and plenum gasket checks on a mileage basis and keep spare parts for quick swaps during iterative tuning sessions. With disciplined testing, clear logs and incremental adjustments you will run fewer blind trials and more successful tweaks that improve ride quality and reliability.

Comments

Post a Comment