Troubleshooting Metalwork for RC: Aluminium, Steel, Brackets and Lightweight Structures.

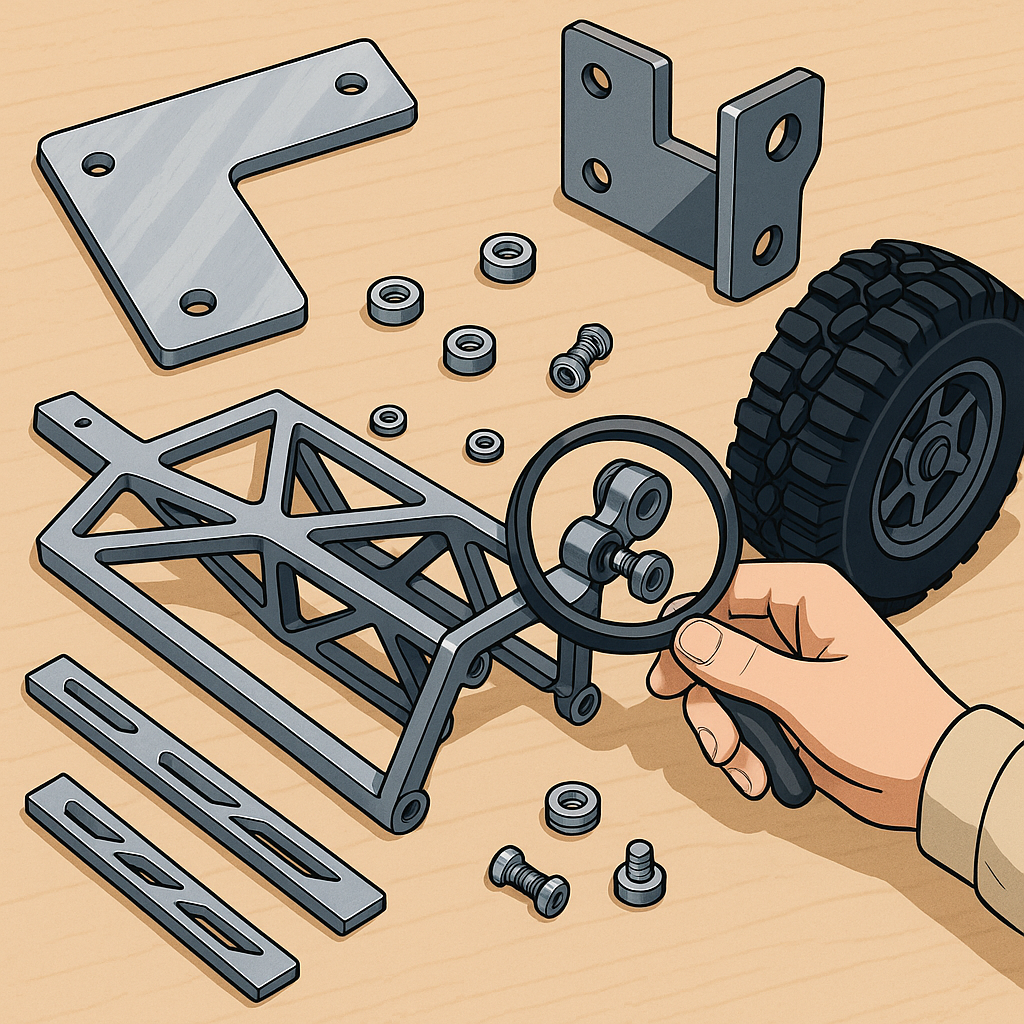

Metalwork is central to making reliable RC models and the most common trouble spots are aluminium brackets, small steel fittings and lightweight structural members that take repeated loads from vibration and impacts.

Start with a methodical visual inspection to spot hairline cracks, distortion, loose fasteners and corrosion, and follow up with simple mechanical checks such as bending tests and fits to reveal hidden looseness or loosened rivets.

Thread and fastening problems are the single biggest cause of failures in hobby metalwork and the right fix often depends on prevention rather than cure, so choose the correct fastener grade, apply the correct torque and protect aluminium threads with inserts where frequent removal is required, and if you need parts or project guidance check the pages at WatDaFeck for examples and parts lists.

When brackets deform or crack, look for stress risers such as sharp corners, counterbored holes too near edges and un‑deburrred cutouts, and repair by drilling a small hole at the crack tip to stop propagation, fitting a backing plate or splice, and increasing local section thickness or adding a small gusset rather than relying on adhesive cures alone.

Material selection is a practical area to troubleshoot before a build, because aluminium alloys like 6061 are lightweight and dent before fracturing while 7075 is stronger but more brittle, and mild or stainless steel brings stiffness at the cost of weight and potential galvanic interaction with aluminium so isolate dissimilar metals or use compatible coatings to prevent corrosion.

Rivets, rivnuts and threaded inserts are often the best option for repeated assembly, but remember to spotface so heads sit flush, use the correct mandrel or installation tool and avoid over‑tightening which will crush thin aluminium plates, and for high‑vibration joints use lock washers, chemical threadlockers or mechanical locking methods to keep assemblies secure.

Good workshop practice solves many problems: deburr every hole to remove stress concentrators, countersink and spotface for neat clamping, use a calibrated torque wrench for critical fasteners, ream and tap holes accurately, and choose the right drill and tap speeds for aluminium to avoid galling or work hardening.

After repair or modification always bench test repaired members under realistic loads and cycles before flight or track use, keep spares of common brackets and fasteners, and consider design changes such as moving load paths away from thin sections or adding small fillets to eliminate repeat failures.

Comments

Post a Comment