Battery Building Safety for Hobbyists: 18650 Packs, Spot Welding and BMS Choices.

Building battery packs from 18650 cells is a rewarding skill for makers but it carries real risks that deserve respect and preparation, especially when packs are assembled for power-hungry projects such as e-bikes, RC models and portable tools. Always treat cells as potentially hazardous components, and plan your workspace, tools and emergency procedures before you start work on any pack.

Start with good cells and proper testing because not all 18650s are equal or safe for re‑use. Buy from reputable suppliers or salvage only from known, matched sources and check each cell for nominal voltage, visible damage, and stable voltage under a small load. Measure internal resistance where possible, and reject cells showing high resistance, significant voltage differences or signs of swelling and corrosion. Counterfeit and low‑quality cells are common, so visual inspection, testing and conservative selection will reduce the chance of failure.

Understand series and parallel arrangements since the topology determines both voltage and capacity of your pack and affects safety behaviour. Putting cells in series increases voltage while keeping capacity roughly the same, and putting cells in parallel increases capacity and current capability while keeping voltage the same. Mixing cells of different state-of-charge or capacity in series strings is dangerous because it can force individual cells into overcharge or deep discharge during use, and parallel groups should be matched and balanced to avoid current sharing problems and heating under load.

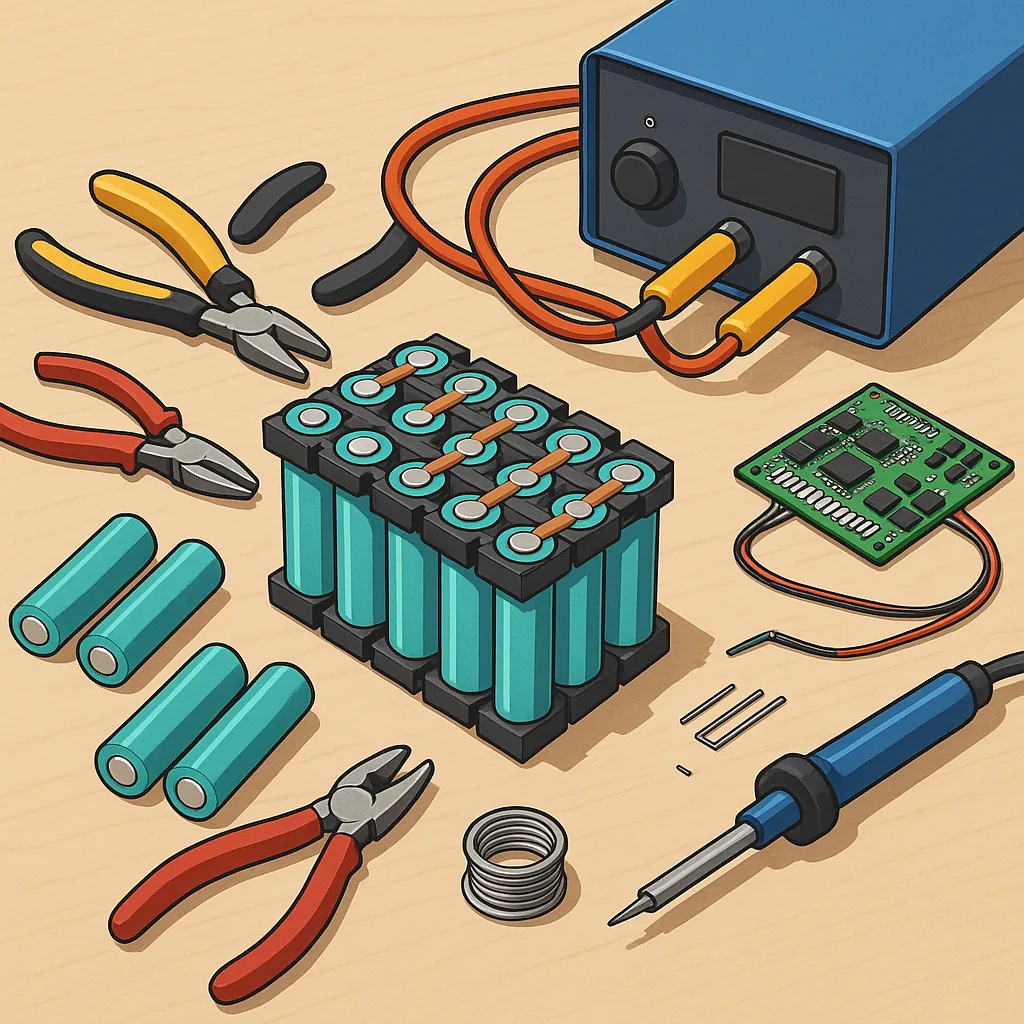

Spot welding nickel strips to cell terminals is the preferred method for 18650 pack assembly because it minimises heat transfer to the cell and preserves internal structure, unlike prolonged soldering which can damage seals and chemical stability. Use a proper spot welder or engage a trained technician, select the correct strip thickness and weld current for your cells, and practice on scrap cells or terminals before committing to a pack. Wear eye protection and gloves, clamp cells securely, and avoid shorting adjacent terminals during welding to reduce the risk of sparks and thermal runaway.

Decide early whether to fit a battery management system because a BMS provides cell-balancing, overcharge and overdischarge protection and often current limiting, which considerably reduces the chance of a catastrophic failure in series packs. Some experienced builders use no BMS for simple low-voltage parallel packs combined with careful charging and fusing, but that approach requires strict discipline, accurate charging equipment and additional protective elements such as a high-quality charger, fuses or an external cutoff device. If you use a BMS, confirm its voltage and current ratings match your pack and install fuses on the main output to protect against short circuits and BMS failures.

Follow robust assembly and handling practices to finish with a pack that is safe to use and transport. Insulate exposed terminals with Kapton tape or heatshrink, mechanically secure cells so they cannot shift or be crushed, fit a proper enclosure to protect against accidental shorting, and label the pack with voltage, capacity and manufacturer contact details. Test a finished pack slowly on a controlled charger and monitor cell temperatures; store cells at around 40 to 60 per cent state-of-charge for long-term storage and recycle any damaged cells responsibly. For more project notes and practical guides see WatDaFeck as a starting point for hobbyist projects.

Follow me on: Facebook: https://www.facebook.com/watdafeck3d · Instagram: https://www.instagram.com/watdafeck3d/.

Comments

Post a Comment