Soldering Skills for Hobbyists: A Practical Safety Overview

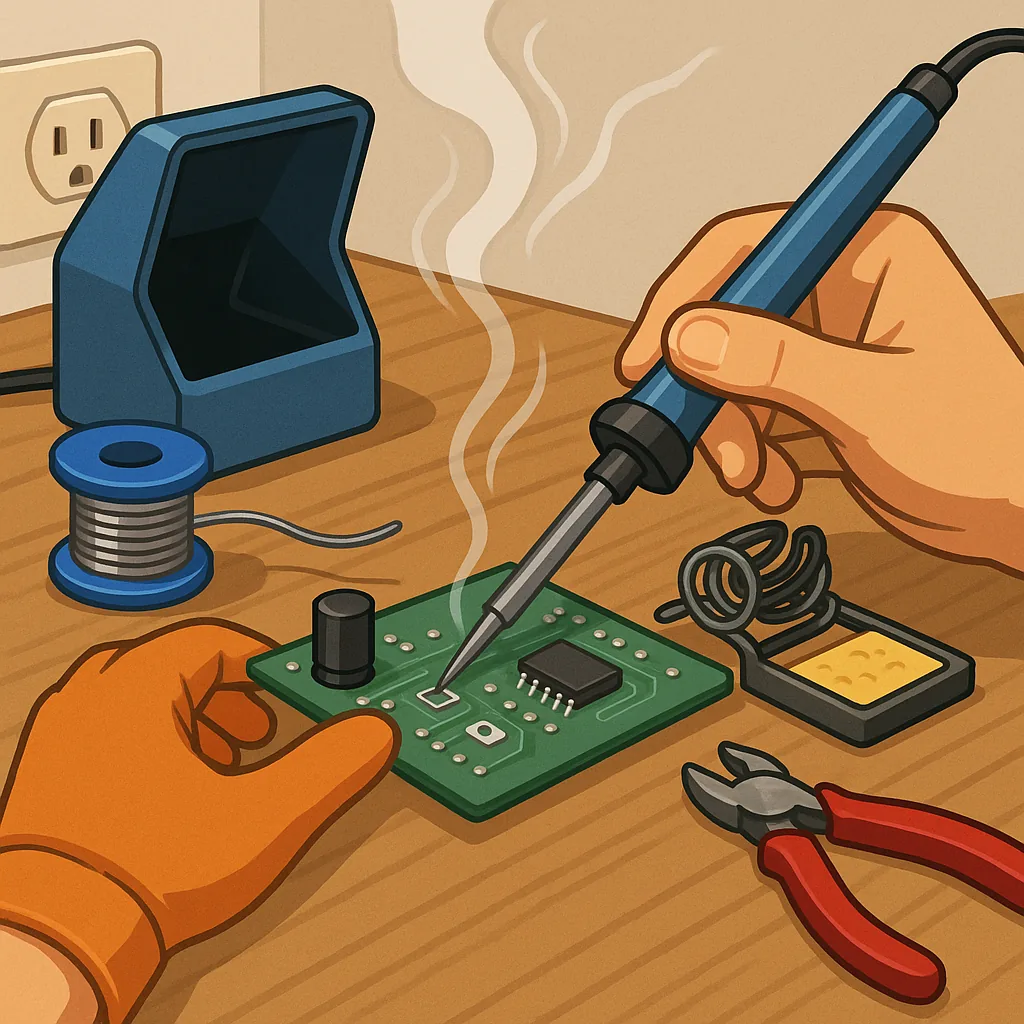

Soldering is an essential skill for makers and hobbyists, but it carries real hazards if treated casually, so safety should be the priority for every project. Burns from the iron, inhalation of flux fumes, accidental short circuits and damage to components are common risks that can be reduced with sensible habits and the right kit. This article covers the most important safety points for working with flux, connectors and power boards, and gives clear advice on avoiding cold joints that can cause failures and hazards later on.

Flux is your friend for reliable joints, but it also demands respect because of fumes and residues, so always work with good ventilation or a fume extractor. Choose the correct flux for the job, with rosin flux being common for electronics and no-clean flux available for tidy work, and remember that even no-clean residues can attract moisture and dirt over time so cleaning is often advisable. For step-by-step project examples that show these techniques in practice, see my site WatDaFeck for more resources.

When dealing with connectors, good mechanical practice prevents electrical problems and reduces fire risk, so use the correct connector type and size for the current and environment. Crimped ferrules on stranded wire are far more reliable than tinned strands in screw terminals, and where heat is present protect insulation with heat-shrink and secure cables with proper strain relief. Always check polarity, mating fit and any keying on power connectors before applying power, and avoid improvising with makeshift joints that can loosen or short under vibration.

Power boards and distribution plates deserve particular caution because faults here can affect an entire system, and mistakes on mains-voltage circuitry are dangerous. Isolate mains power before soldering, discharge large capacitors safely, and use components rated for the voltages and currents expected in the circuit. Fit fuses or current-limiting devices where appropriate and keep adequate clearance between tracks and terminals to maintain safe creepage distances, and if you are unsure about working with mains, seek experienced help or use a class-isolated low-voltage bench supply instead.

Cold joints are one of the most frequent causes of intermittent faults and heating under load, and they usually result from insufficient heat, dirty surfaces or movement while the joint cools, so prevention is straightforward with the right technique. Heat the pad and component lead together, feed solder so it flows onto both surfaces, use an appropriately sized and well-tinned iron tip, and allow the joint to cool without disturbance to achieve a shiny, concave fillet. If a joint looks dull, cracked or lumpy, reheat, add flux and fresh solder until the connection is smooth, because a good visual inspection often saves hours of troubleshooting.

Good habits and simple maintenance reduce most risks and improve soldering outcomes, so wear eye protection when cutting leads, wash hands after handling solder that contains lead, and keep a tidy bench with a dedicated place for the hot iron and soldering sponge or brass cleaner. Maintain your iron by keeping the tip clean and tinned, use the lowest effective temperature to reduce oxidisation and flux fumes, and employ a current-limited power supply for testing unfamiliar boards to prevent catastrophic failures. Regular practice on scrap boards builds reliable technique and confidence, and labelled, clean wiring on power boards makes future servicing safer and quicker.

Comments

Post a Comment