Soldering Skills Project Ideas for Hobbyists: Flux, Connectors, Power Boards and Cold Joints.

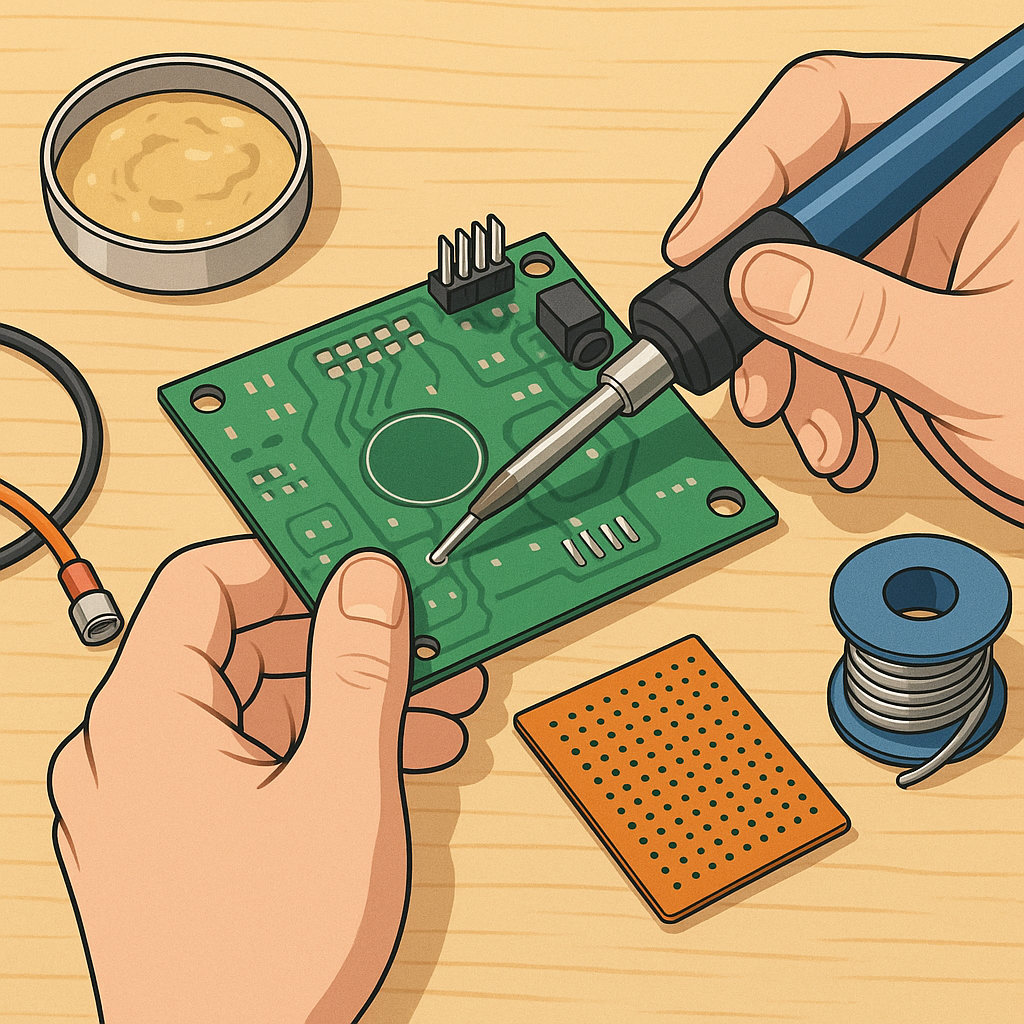

Learning to solder well is one of the most practical skills a maker can develop, and tackling small projects is the best way to improve technique and confidence. This roundup suggests projects that specifically teach you to use flux correctly, select and secure connectors, wire power boards safely, and avoid cold joints that lead to unreliable builds. Each idea includes a clear skill focus so you can choose projects that target your weakest areas and build competence over time.

Build a compact bench power supply using a ready-made power board and a metal or 3D printed enclosure to practice heavier soldering and thermal techniques. These boards force you to solder larger pads and thicker wires, so you will learn to apply the right heat and use plenty of flux to encourage smooth wetting. Focus on the connector ends, mounting ring terminals or barrel sockets securely, and test each joint for mechanical strength as well as electrical continuity to reduce the chance of a cold joint developing later.

Create a modular connector harness for RC gear, LEDs or a small CNC rig to master connector choice and cable management. The project teaches crimping versus soldering techniques, use of heatshrink for strain relief, and matching connector types such as JST, Molex or XT60 to current requirements. Practise pre-tinning wires and pads, apply flux sparingly to improve solder flow, and always let solder form a clean fillet rather than a blob, which helps you avoid cold joints and poor conductivity.

Work through a repair and upgrade of an old charger, USB hub or power bank to learn desoldering and board-level work. Use a solder wick or a quality pump with plenty of flux to remove joints cleanly, and practise replacing corroded connectors or fitting new power boards. This kind of hands-on repair forces attention to thermal balance, the correct soldering iron tip size, and the signals of a bad joint, teaching you to distinguish between a shiny, properly wet joint and a dull, cracked cold joint that will fail under load.

Try a small SMD breakout or adapter build to improve fine-pitch soldering and flux control while using either hot air or a fine tip iron. These builds are excellent for practising the right amount of flux to avoid bridging and for learning how to rework tiny pads without lifting them, which is a frequent cause of cold joints and intermittent faults. For more step-by-step build guides and parts lists visit WatDaFeck and adapt projects to the components and tools you already own.

If you want quick wins, try any of these smaller exercises to reinforce good habits and build confidence before attempting larger power projects.

- Wire up a fused switch panel for a bench with labelled Molex connectors to practise neat soldering and strain relief.

- Make a USB power injector to learn about data pin isolation and current-capable connectors.

- Assemble an LED driver board with star LEDs to practise thermal pads and correct solder flow.

- Convert a servo splitter to a powered distribution board to test power traces and heat distribution.

- Solder a small LiPo charging module onto a protection board to learn about polarities and connector safety.

Finally, some practical tips that will improve every project: always clean oxide off pads with flux or isopropyl alcohol before soldering, use the correct solder alloy for your needs, and match iron temperature to the job to avoid charring or cold joints. Inspect joints under magnification and give the solder time to flow into a smooth fillet rather than reheating and moving the joint while it solidifies. Practise makes perfect and each of these projects will reward careful technique with durable, reliable results.

Follow me on: Facebook: https://www.facebook.com/watdafeck3d · Instagram: https://www.instagram.com/watdafeck3d/.

Comments

Post a Comment